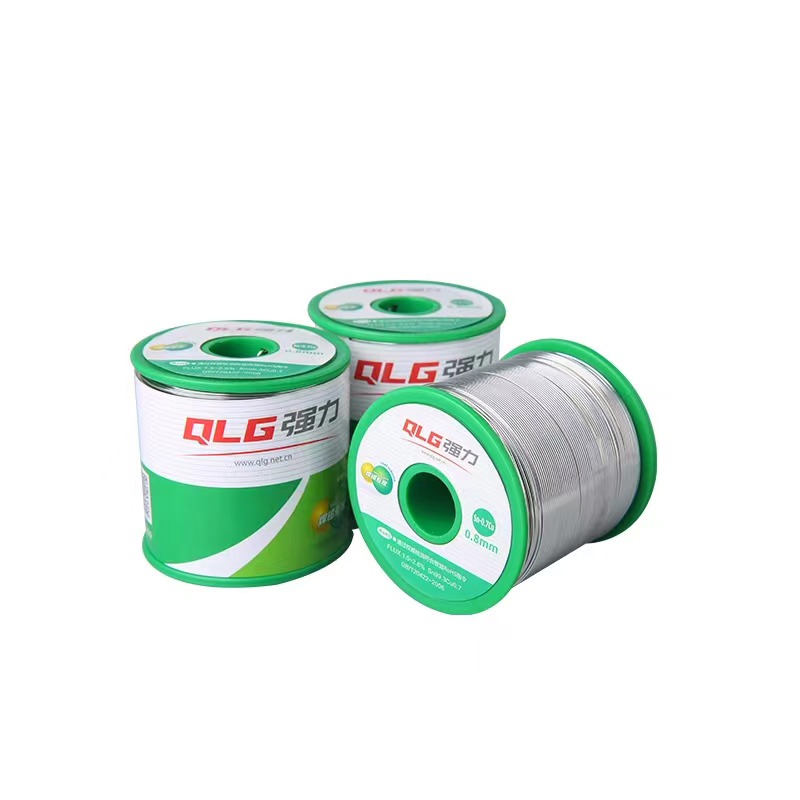

Sn99.3Cu0.7 Copper Tin Lead Free Solder Bar

Lead-Free Sn0.7Cu is composed of 99.3% tin, and 0.7% copper. QLG Bar Solder conforms and exceeds the impurity requirements of IPC J-STD-006C and all other relevant standards. It is desirable for use in common metal equipment, copper tubes, and copper plates. This product is a conventional type of environmentally-friendly solder by adoption of lead-free soldering technology.

Our company has obtained Reach certificate and RoHS certificate for lead-free type products, as well SGS certificate. All Sn99.3Cu0.7 lead-free solder wires made by our company can reach the EU RoHS standards.

Application

The Sn0.7Cu solder wire can be used for the soldering of the precise computer chips, mobile phone chips, LED, printed circuit board (PCB), and a variety of high-precision electronic circuit boards, among others. Meanwhile, it is suitable for the restoration of mini-sized electronic equipment.

Parameters

|

Spec |

Sn99.3/0.7Cu |

||||||||||

|

Melting point |

227℃ |

||||||||||

| Specific Gravity |

7.4g/cm3 |

||||||||||

|

Weight |

500g/pcs,1000g/pcs, other weights can be customized |

||||||||||

|

Ingredients |

|||||||||||

|

Sn |

Ag |

Cu |

Bi |

Sb |

Zn |

Pb |

Ni |

Fe |

As |

Al |

Cd |

|

99.3±1.0 |

0.1 |

0.7±0.2 |

0.1 |

0.1 |

0.001 |

0.07 |

0.01 |

0.02 |

0.03 |

0.001 |

0.002 |

Features

1.High Electrical Resistivity and Electrical Conductivity

Due to the addition of copper, Sn99.3Cu0.7 solder bar allows the electronic components to produce relatively high electrical resistivity during the soldering process.

2.Appropriate activated rosin flux provides distinguished soldering effect, fast soldering speed, as well as extremely good fluidness.

3.High Melting Point

With high melting point, our product is ideal for the soldering of electronic equipment at high temperature. A combination of tin and copper allows this environmentally-friendly lead free solder wire to have high melting point.

- Produced from High Purity Metals

- Special shaped anodes offering maximum surface area and minimal bending

- Reduces Scrap

- Common Plating Anode alloys are Pure Tin, Pure Lead, Tin/Lead, and various lead-free alloys

- Other alloys are available upon request.