China wholesale Tinning Paste For Copper Manufacturer – No-Clean Liquid Solder Flux – QLG

China wholesale Tinning Paste For Copper Manufacturer – No-Clean Liquid Solder Flux – QLG Detail:

Product Description

We offer a full line of Water-Soluble, Lead-Free, halogen-contianed, halogen-free and No-Clean Flux for wave soldering applications. As well special flux for photovoltaic, battery, HASL and stainless steel.

Our lead free solder flux is often used for the wave soldering process, because its wetting property is specially designed. It allows the solder joints to be bright and full. Moreover, the surface of the circuit board is dry and clean.

Owing to its outstanding soldering performance, our lead free solder flux is able to reduce the bridging or other defects as much as possible during the wave soldering process. Furthermore, our product is applicable for the wave soldering, foam type soldering, spray type soldering, and other types of processes.

Product Offerings

● No-Clean

● Photovoltaic

● Water-soluble

● Battery

● HASL

● Stainless steel

|

Item |

Spec |

Properties |

|

No-Clean |

QL-F1202 |

Low cost and weak acid |

|

QL-N99-5 |

Lead-Free, Halogen-Free, and High compatibility |

|

|

QL-N995 |

Wave soldering and High compatibility |

|

|

QL-N999 |

Solder joint thread |

|

|

QL-F290 |

Lead-Free and For Nickel soldering |

|

|

Photovoltaic |

QL-F501A |

Low solid content, good activaty and no residue |

|

Water-soluble |

QL-S65-3 |

Water-based, good activaty and weak acid |

|

Battery |

QL-F649X-1 |

Low cost |

|

HASL |

QL-F1207 |

HASL |

|

Stainless steel |

QL-F3808 |

Stainless steel |

FAQ

1、What are the common soldering methods?

The manual soldering, wave soldering, dip soldering, elective soldering and the reflow soldering.

2、Where are the solder products applied?

Both solder wire and solder bar widely are applied in metal equipment, electronic components, communications equipment, electronic instruments, and more.

Solder paste is mostly used for the soldering of electronic components of SMT, SMD, PCB and LED.

3、Why does the tin splatter when the wire is soldered?

When the amount of rosin flux in solder wire is excessive, we advise customers to reduce the amount of flux to 2%.

4、What is our production capacity?

Our monthly production capacity is 500 tons for solder materials and 2000-3000L for liquid soldering flux.

5、What product certificates have we achieved?

The lead-free solder materials in our company has already passed multiple certifications, such as SGS, RoHS, REACH, and more. Our company has obtained the ISO 9001 certificate.

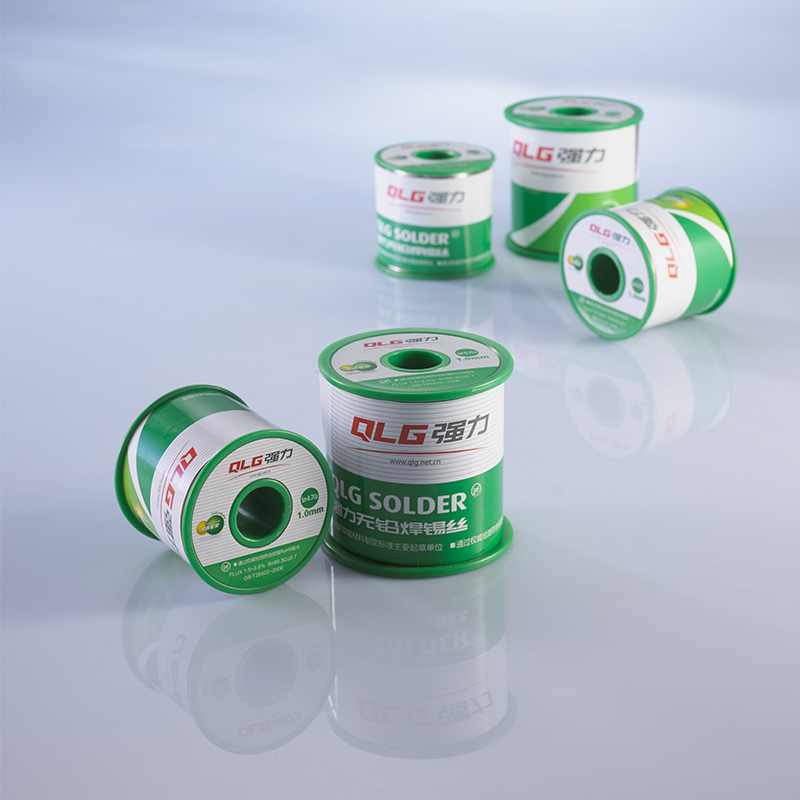

Product detail pictures:

Related Product Guide:

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for China wholesale Tinning Paste For Copper Manufacturer – No-Clean Liquid Solder Flux – QLG , The product will supply to all over the world, such as: Nigeria, Mali, Palestine, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a professional engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We are your best choice.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.